Molding the Next-Gen Workforce

Mike Parker never pictured himself a schoolmaster. He’s the president of AFS Corporate Member Supplier Epic Machine Inc., a 41-year-old precision machining and custom tooling operation in Fenton, Michigan, about 60 miles northeast of Detroit. His company serves foundries all over the country with tooling, precision tooling and equipment components, as well as machines for castings. For the last seven years, he’s also been the founding owner of Epic CNC Training Academy––it was, in the end, the best solution he could think of for curing the severe deficit of young workers with ready-to-work skills.

After witnessing the deterioration of the skilled manufacturing labor market in his state, he resolved to make a difference, to turn the tide. Young people have been told success only comes from a four-year college degree, and even local two-year associates programs, he observed, were falling short in their practical training of metals manufacturing students. So Parker did what seemed the logical thing: He joined the advisory boards of three college programs and a local skills training center. His mission was to help program coordinators and instructors better understand what industry needs from their graduates.

“The real problem is, they have instructors who were never true manufacturers,” said Parker, “and so they can’t really teach them and train them into things we really need.”

Still attempting to work within the boundaries of an existing but flawed system, Epic hired the best of the graduating pool, but they never lasted long.

“They would tell everybody in the shop about their talents and degree, but when they started asking for help, nobody would help them,” said Parker. “They’d say, ‘Oh, you’ve got a degree; you figure it out.’”

A few rounds of that routine and Parker called a timeout. Together with longtime friend Mark Dyer, retired from General Motors, Parker reverse-engineered the situation and crafted a document with the qualifications they wanted in an entry-level employee. A skillset now on paper, Dyer developed a full-blown curriculum––and a revolutionary training academy was born. Today, Parker said, Epic’s Academy can take a cook at a fast-food joint (or any interested young person, that matter) and turn them into a great machinist.

Better This Way

Creating a separate training program replete with its own instructor, Dyer, plus classroom space, supplies and equipment has been a serious investment of nearly half a million dollars, and despite an annual stipend paid back to Epic Machine, the company loses over $60,000 a year by hosting a school under its roof. But developing the program the way it did means Parker’s skilled machining team isn’t wasting time training rookies, so productivity and profitability aren’t compromised.

The Academy has fulfilled the passion Parker and Dyer have for seeing young people succeed while at the same time contributing tangible answers to an industry crisis, putting a priority focus on final outcome––something college programs don’t, according to Melinda Keway, Epic’s vice president, Academy administrator and Parker’s 40-year-old daughter and soon-to-be successor.

“Our philosophy is not about putting butts in seats,” she said. “It’s about making quality machinists. The colleges need to shovel people through; they’re in it to make money. They don’t care whether their students are job-ready or not; they just keep funneling more people through the program. We’re about quality, not quantity.”

Epic’s Academy is an eight-week, hands-on class for which students pay a $9,600 tuition fee. Having turned out 36 graduates since its inception and successfully placing every student who wants a job, the CNC Academy not only gives Epic management direct control over what’s taught and how––Parker and Keway also have a front-row seat and first pick on the cream of the crop. They’ve cornered their own market on keeping their workforce top notch, says Parker, and that’s a message he’s eager to communicate.

“I want our customers to know that Epic plans on being around for a really long time,” he said. “Instead of letting our workforce age out and retire, we want to make sure we have new blood coming along behind ... so [foundries] will always be able to depend upon Epic Machine.”

Gaining Momentum

Word of the Academy’s outstanding results has seeped out. Manufacturers are waiting in line to hire those completing the program, which offers two tracks; students choose either milling or lathing, so upon completion they’re proficient in one specific skill.

Recognized by the state of Michigan as a training institution and showcased by the governor at an Economic Summit in Detroit the year it opened, the Academy quickly earned a stellar reputation that soon reached the ears of state Career Alliance staff while visiting shops that were hiring Epic CNC’s students.

“We had a group come in here that said, ‘The governor will give you more than a million dollars to expand this program because we’re getting such high reviews on you,’” Parker said. “I said, ‘I’ve got two questions: (1.) Do I have to use Michigan Education Association curriculum and (2.) Do I have to use their employees?’ They said yes, and I said ‘Keep your money. It doesn’t work.’

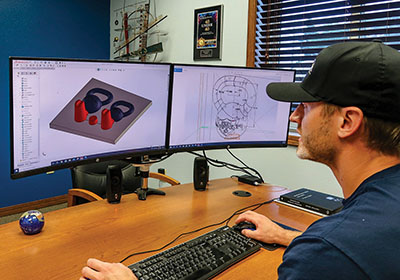

“Here, each student gets their own machine five days a week.They’re getting real hands-on experience every day. Mark teaches how to read blueprints using standard GD&T charts, and they’re using General Motors and Chrysler, Caterpillar and John Deere blueprints rather than something out of a textbook that somebody who was never a machinist dreamed up.”

Dyer’s training is indeed comprehensive, beginning with safety/OSHA from Day 1, then ranging from math and blueprints to programming and operating both manual and CNC machines, as well as developing proficiency with Mastercam software. Ultimately, he has students designing and making their own projects, continually challenging their limits and expanding their abilities. When they leave, they are armed with reference materials plus a thumb drive loaded with their own work.

“When an employer says, ‘Show me something you’ve done,’ they can say, ‘This is the print I had, this is the program I wrote, and this is the part I created,’” Dyer said.

“I also like to teach them some things about what it’s like to work in a factory or a machining facility. I tell them, ‘You need to be there on time, every day. You need to realize you don’t know everything, and you’re going to be dependent on people around you to continue your education––so treat people with respect.’ And I try to give them a little insight about getting along with different personalities.”

Marketing at the Movies

Reaching young men and women with the opportunity for a good-paying career ought to be as easy as drawing ants to a picnic, but many school counselors, parents and other influencers still propagate old stereotypes and steer kids to four-year colleges, regardless of how they’re wired. That’s why Epic makes a point of targeting both older adults and young people in their CNC Academy marketing.

They’ve had positive feedback from their television ads specifically aimed at an older demographic during the 6 o’clock news hour, for example. Epic also attracted several parents and grandparents to an open house for the Academy.

One of Epic’s most innovative marketing efforts was cooked up by Keway to target young people. The company developed a 30-second commercial set to a beat and bought ad time in the local movie theaters.

“Earn more, be more,” the voiceover says during the visually powerful video that creates a compelling message for a promising future.

Earning and doing more is what students are doing with their Epic CNC certifications. Dyer cited a fellow who made a name for himself doing tight tolerance work at a company in Saginaw, then took a better job in Lansing where he advanced into a leadership role, then moved north to Traverse City and is climbing the management ladder with consistent pay increases.

Keway said a manufacturer in Detroit decided to have a little contest when he discovered the Academy. Having been disappointed by hires from several colleges, he now hires from just one trade school. However, he opted to put an Epic CNC grad against a new hire from his preferred institution.

“Four weeks later I called up and asked how our student was doing,” said Keway. “He said, ‘I’m glad you called—I had them both take the mechanical aptitude test, and your student did far better. Your student was able to turn on the machine and actually make it run on the very first day. And now three weeks into the training program, we have moved him into the programming course. And if he does as well in the programming course as he did in the initial training session, then he’ll be making $18 an hour ... I don’t know how a student that only has eight weeks of training can be better than a student who took two years.’”

Foundry Owner Fires Up Iron Warrior Program

Turn the compass westward from Michigan with about 1,000 miles on the odometer, where Dakota Foundry, an AFS Corporate Member based in Webster, South Dakota, is stoking up a brand new, built-from-scratch training program.

Kory Anderson, whose fabricating company, Anderson Industries, bought the foundry in 2015, is a self-made trailblazer who’s taking extreme action to fight the cultural and educational stigma that has gnawed away at the skilled trades workforce since the 1980s. He is preparing to launch his Iron Warrior program—

dakotafoundry.com/ironwarrior—as two eight-week sessions, the first comprising character-development, physical fitness, nutrition and mental discipline. Part 2, the Advanced Operator program, is an optional continuation Anderson said will amplify the regimens from Part 1 while providing deep technical instruction on such topics as 3D CAD modeling and the designing of castings, 3D printing, solidification and more.

Anderson himself designed his own educational path, combining hand-picked mentors, hands-on, shop-floor learning, and coursework from traditional college, which he left early to start his own business. With Iron Warrior, Anderson will be offering young people a road less travelled but one that’s at least already paved. Scheduled to have begun this year but derailed by COVID-19, the program, he hopes, will launch either this winter or next spring. It will be the culmination of a decade-long passion and a lifelong personal mission.

“Along my journey, learning and achieving became a passion of mine, and then I started to get really interested in what fuels peak performance in individuals,” Anderson said. “So I have really studied that for about the last 10 years––not just for myself to be able to perform at my highest level, but how can I help and train others so they can perform at their highest level. I believe one of the reasons I’m here on this earth is to help as many people reach their full potential as possible. It’s just something I really care about.”

His pursuit of peak performance and mental resiliency led Anderson into a close study of the military, including Navy SEALs and Green Berets, who have mastered mental toughness, he said. Just as important are humility and the ability to work effectively in a team, he added.

“The Iron Warrior program is a combination of Special Forces training and a nutrition program to develop character, mixed with a hands-on skilled apprenticeship. In my opinion, it’s very difficult to train the knowledge and the skills without the strong character qualities,” he said.

In the end, Anderson wants to give young people the opportunity to lay a foundation to become an elite performer in life and to meet their own goals. His ideal candidates are between the ages of 18 and early 20s so they can still go to college if they want to pursue higher education—he’s also structuring the program to accommodate remote learning for those who are already employed in a foundry. Unbound by geographic borders, he’ll market Iron Warrior through social media and hopes it’ll eventually grow to a national level.

Counting the Value Rather Than the Cost

The cost to participants will be $6,000, but like Epic Machine well knows, the fees will only partially defray Anderson’s investment––creating a company-owned and -operated training program is no money-making proposition, he asserted.

“But it’s something that’s important for American manufacturing, and specifically the foundry industry ... to have and maintain the ability to build a strong workforce and for us to remain globally competitive,” he said.

Another plus: “A lot of the people who go through the program might end up being our own employees,” he added. “I’m sure the program will cost us more in the short term, but my vision is that we’ll help other foundries become stronger ... for the long game, I believe it’s the right thing to do.”

To help financially buoy those who enroll and offset its own program expenses, Dakota Foundry is now marketing the Iron Warrior line of kettlebells at ironwarriorshop.com. Anderson says as soon as the training is up and running, he plans to have students make some of their own fitness and training equipment at the foundry.

“Our lines of fitness products are helping spread awareness about our program, and then the proceeds we make from those products are being put into a fund to help sponsor students through the Iron Warrior program,” said Anderson. “So people that buy Iron Warrior products are essentially helping to fund skilled workforce education.”

What About the Rest of Us?

Most foundries are not going to get into the business of setting up their own training academies. But plenty of options are available to anyone who wants to contribute toward the recruitment and retention of the industry’s next generation of skilled workers and leaders.

A good place to start may be with the young people you have right now, according to Anderson.

“We’re not interested in what we don’t know,” he said. In other words, the more a foundry can expand a new hire’s knowledge of processes and products, the greater their appetite will be to learn and grow in the company.

To feed that appetite, Anderson subscribes to the AFS Institute e-Learning program and actively and immediately immerses his new employees in the myriad video and e-learning programs; with 110 courses to choose from, he said it’s an easy way to establish some knowledge to help foundry rookies begin to understand what they’re doing and why each aspect of metalcasting is important. (For details, visit afsinc.org/e-learning) Subscribing member companies appoint a staff liaison to coordinate training with the AFS Institute, but its director, Jen Christian, said she takes most of the administrative burden away from the foundry so it can stay focused on its own work.

“It’s really not expensive,” Anderson added. “A foundry can just have their team spend an hour a week watching videos––getting educated is relatively simple.”

Be the Change

While most of the foundry community bemoan the workforce crisis, Anderson points to the many positive actions owners and their staffs can take to make a difference.

For the social-media savvy, for example, start posting on Instagram––the object, after all, is to reach young people, so hang out where they hang out. Anderson started a “Caught Using Castings” series on his Instagram account and shares a photo and brief explanation whenever he’s out and recognizes an incognito casting at work.

Anderson is also a fan of internships––he suggests partnering with local college programs to give future applicants the hands-on experience they need for the jobs you want them ready for.

And start building relationships with local high schools, especially counselors and shop instructors. When they know who you are, they’ll be more inclined to accept your invites for tours. And make use of the successful young employees working at your company—let them be your spokespeople with young audiences.

“Have them speak out and share their stories, even if it’s within their local communities,” he said.

The metalcasting industry has a powerful message to communicate to kids and their parents, Anderson said: “You don’t have to have a four-year degree or go to university to be successful in America.”

Click here to read the article in the digital edition.