Casting Competition 2023

Casting of the Year

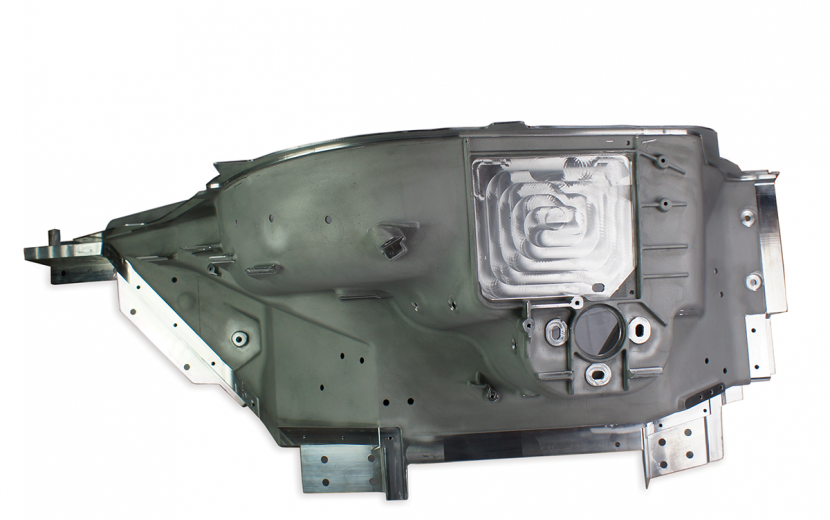

A completely clean-sheet design with no predecessor, the 59.5-lb. casting measures in at 58.5 x 22.5 x. 33.3 inches. It was made with TEI’s own proprietary sand cast alloy developed for high ductility (bendability), an essential property for the automotive industry. Produced with low-pressure precision sand casting, the rear rail combines the rail, shock tower, and wheel well into a single casting, thereby replacing many stamped components in a traditional design.

Outstanding Achievement

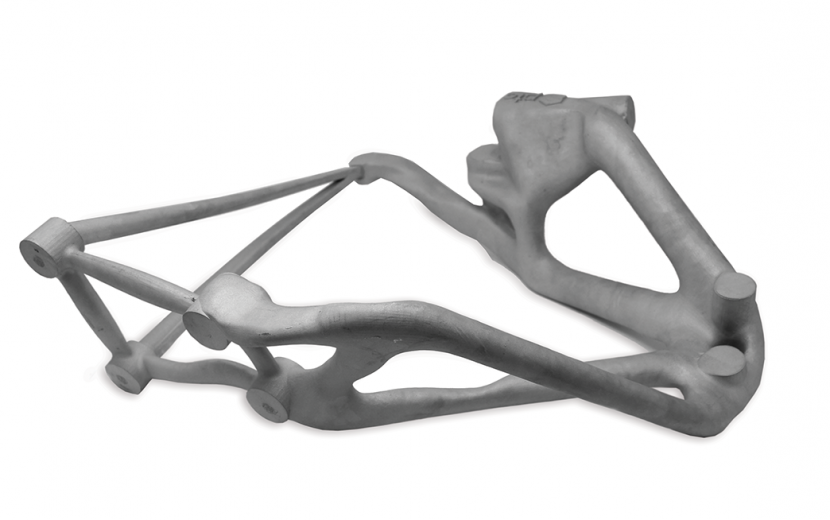

Engine Mount Casting

O’Fallon Casting (O’Fallon, Missouri)

Material: A356-T6 aluminum; Process: Investment casting; Weight: 10 lbs.; Dimensions: 18 x 18 x 11 in.

O’Fallon Casting (O’Fallon, Missouri)

Material: A356-T6 aluminum; Process: Investment casting; Weight: 10 lbs.; Dimensions: 18 x 18 x 11 in.

Outstanding Achievement

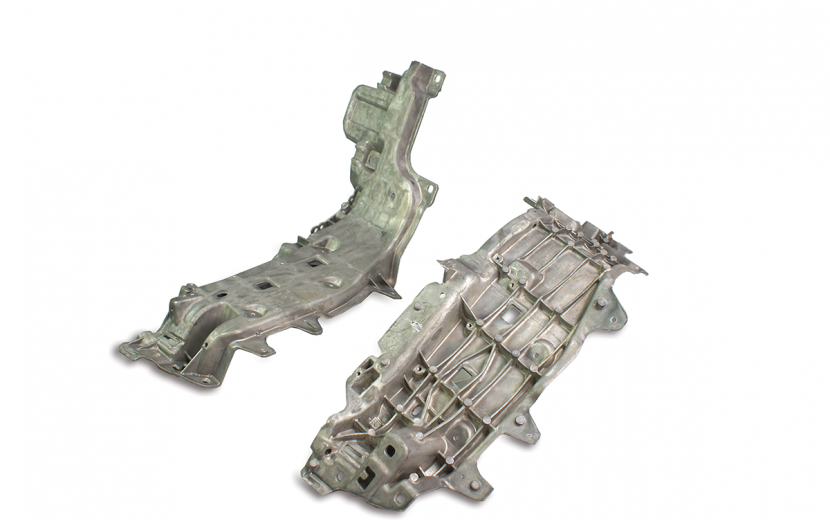

Rear Support Bracket

Meridian Lightweight Technologies (Strathroy, Ontario, Canada)

Material: AM50A magnesium alloy; Process: High pressure diecasting; Weight: 1.93 kg.; Dimensions: 30 x 50 x 56 cm; Application: Mercedes-AMG

Meridian Lightweight Technologies (Strathroy, Ontario, Canada)

Material: AM50A magnesium alloy; Process: High pressure diecasting; Weight: 1.93 kg.; Dimensions: 30 x 50 x 56 cm; Application: Mercedes-AMG

Newcomer of the Year

Sensor Pod

K&H Precision Products (Honeoye Falls, New York)

Material: A356 aluminum; Process: Sand casting; Weight: 3.25 lbs.; Dimensions: 7.75 x 3.25 x 3.5 in.; Application: Automotive.

K&H Precision Products (Honeoye Falls, New York)

Material: A356 aluminum; Process: Sand casting; Weight: 3.25 lbs.; Dimensions: 7.75 x 3.25 x 3.5 in.; Application: Automotive.

Best Example of a Casting Conversion

Burner Box

Metal Technologies Inc. (Auburn, Indiana)

Material: Ductile iron; Process: Vertical green sand casting; Weight: 15.3 lbs.; Application: Commercial/residential HVAC.

Metal Technologies Inc. (Auburn, Indiana)

Material: Ductile iron; Process: Vertical green sand casting; Weight: 15.3 lbs.; Application: Commercial/residential HVAC.

Achievement by a Small Business

Ground Turbine Air Inlet

Morris Bean & Co. (Yellow Springs, Ohio)

Material: A356 aluminum; Process: Gravity pour nobake casting; Weight: 2,286 lbs.; Dimensions: 73 x 30 in.; Application: Power generation.

Morris Bean & Co. (Yellow Springs, Ohio)

Material: A356 aluminum; Process: Gravity pour nobake casting; Weight: 2,286 lbs.; Dimensions: 73 x 30 in.; Application: Power generation.

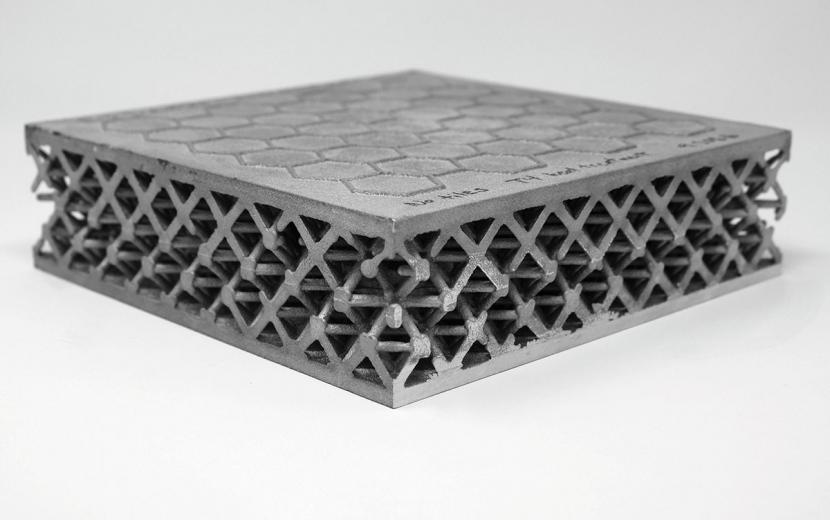

Best Prototype or Innovation

Metal-Ceramic Lattice Structure

Virginia Tech - Kroehling Advanced Materials Foundry (Blacksburg, Virginia)

and Eck Industries (Manitowoc, Wisconsin)

Material: A 206 alloy with 1% TiC nanoparticles; Process: Gravity-pour sand casting; Application: Military and commercial.

Virginia Tech - Kroehling Advanced Materials Foundry (Blacksburg, Virginia)

and Eck Industries (Manitowoc, Wisconsin)

Material: A 206 alloy with 1% TiC nanoparticles; Process: Gravity-pour sand casting; Application: Military and commercial.