Picture Perfect Casting

LA Aluminum Casting makes parts that have to look great and function precisely.

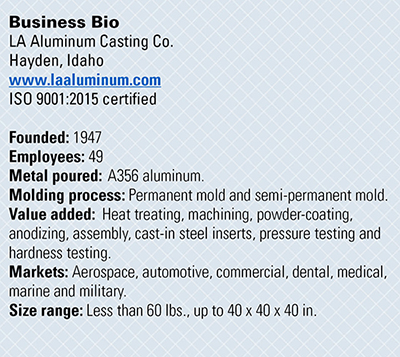

AFS Corporate Member LA Aluminum (Hayden, Idaho) has been in business for over 70 years, and Robert Oswald has spent time in the foundry since grade school. During his years running the company, Oswald has looked for balance between stretching the foundry’s capabilities to meet customer needs (and grow in the process) and drawing the line against work that will lose money.

“There is a cost associated with quality. I’ve learned you can’t always say yes to a customer,” Oswald said. But he isn’t afraid of taking on difficult work that could be a good fit for the foundry. By working through tough challenges to find a cost-effective solution, LA Aluminum continues to expand its capabilities and expertise, so the next challenge is within closer reach.

“It takes a will to want to get it worked out,” Oswald said. “It’s more a thought of when we will get it worked out, not if.”

Many of LA Aluminum’s parts are in applications where they are visible to the end-user, such as the articulating arm in a dentist chair that holds dental tools, the sneeze guard in a restaurant, or a hand-held instrument. So, the parts have to meet the mechanical requirements while also looking perfect. This was true even with a diffuser ring for a submersible dewatering pump.

“Aesthetics for us are important because when people see our products, we want them to see it looks better and has a higher quality than our competitors,” said Jed Hinkins, the general manager at customer Peak Mechanical (Osburn, Idaho).

LA Aluminum helped Peak Mechanical enjoy the improved aesthetics of a permanent-mold cast part while figuring out ways to incorporate cast-in holes and inserts to lower finishing and machining costs. This helped the ROI for Peak Mechanical and opened the door for more of their parts to be cast in permanent mold at LA Aluminum.

“Along the stages of part development, we want to work with the customer so we can say this will work or this might cut cost,” Oswald said. “We also will use simulation software to verify a design.”

LA Aluminum performs its own machining and powder-coating in-house, along with some assembly when needed. The facility is busy. Close to 50 people work two shifts at the plant to produce castings that will be shipped throughout the country. And the orders are growing.

“July was a record sales month for us,” said Sarah Oswald, sales & marketing manager, LA Aluminum. “It was 14.8% higher than our last highest sales month, which was in 2014. So, the business is expanding.”

The fiscal year that finished at the end of June was also a high-water mark for the company, and sales were up 11% over the previous year. The new work is coming from both existing and new customers, particularly in dental, military, medical, and food equipment manufacturing. LA Aluminum has between 30 and 40 active customers, with 15 of those making up most of its dollar volume.

“We are growing, but we don’t want to push so hard that we let customers down,” Robert Oswald said. “So, we are trying to keep up with that growth and keep our customers happy.”

PHOTO GALLERY: LA Aluminum Casting Co.

This year, LA Aluminum added a new machining center in its tooling shop with a larger capacity to create molds faster and bigger, when necessary. The same dental equipment manufacturer that commissioned the articulating arm inquired about having larger arms for a new product line made there, too. The new CNC machine is able to machine molds large enough to cast them.

The casting facility also recently purchased additional coremaking equipment to help meet extra core demand.

“A lot of our new business requires cores, and it all picked up at the same time,” Sarah Oswald said.

Like many manufacturers in the U.S., succession and a steady workforce is on the mind of Robert Oswald. Last year, LA Aluminum hired an HR manager for the first time to help keep the facilities staffed, the employees trained, and the business in compliance with employment regulations. The company has hired interns from local technical colleges who are helping major projects move along while learning about the industry in the process. The hope is to find a fit for a permanent position at LA Aluminum.

“Because of the aging population, we don’t always have replacements with the same expertise,” Robert Oswald said. “But it’s inspiring that there are young people out there acquiring these skills, and they enjoy them and are good at them.”

For Robert Oswald, who was foundry manager at 19 and running the company at 27 after his parents passed away, his own successor is very much on his mind too. Retirement is still a couple years away, but the succession planning has started with daughter Sarah, who will be transitioning into the leadership role.

Sarah Oswald has entrepreneurial experience outside the foundry, as a horse trainer and the owner of a pressure washer window cleaning business. She came to LA Aluminum in 2014 and has been learning the ins and outs of operating a metalcasting facility since.

“He’s been asking me about taking this on since I started,” Sarah Oswald said. “It grew on me over time, and I have come to enjoy working in manufacturing and working with the employees and the customers.”

Sarah Oswald will be the third generation leading LA Aluminum, which was started by her grandparents Robert Oswald Sr. and Helen Oswald in California in 1947. In lean times, her grandfather went on sales calls while her grandmother stayed back to pour the castings. When the couple fell in love with the Northern Idaho area and decided to move the business there in 1972, their son, Sarah’s father Robert Oswald Jr., worked 100-hour weeks as a 19-year-old to get the new plant up and running.

Now LA Aluminum is an established business embarking on new initiatives with new customers, new applications and new technologies, and it will be Sarah Oswald’s challenge to navigate the ebbs and flows of the metalcasting business.

“We’ve been through very lean times and some good times,” Robert Oswald said. “As in life, everything runs a cycle. There are no guarantees; we just keep working off determination.”

Click here to see this story as it appears in the September 2019 issue of Modern Casting.